OEM Manufacturer Inkjet Sublimation Paper - M3300 Industrial Printer – JHF

OEM Manufacturer Inkjet Sublimation Paper - M3300 Industrial Printer – JHF Detail:

Multifunctional Hybrid Printer

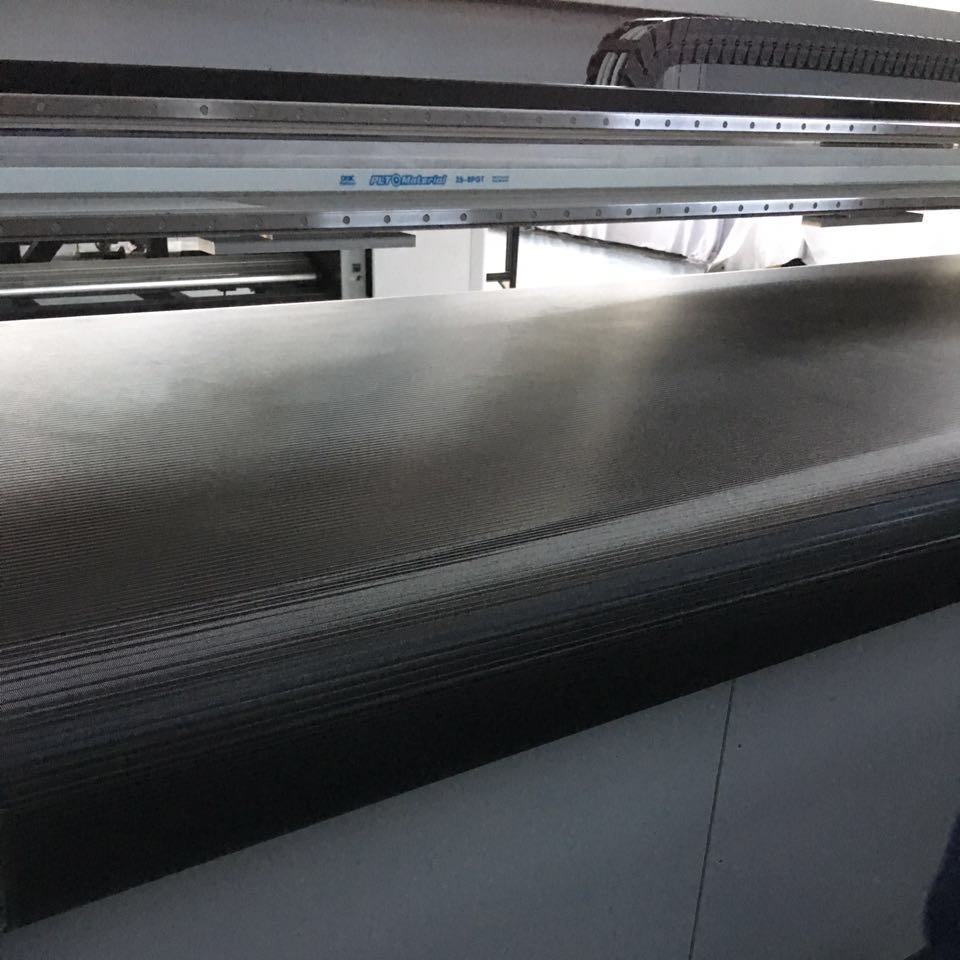

Superb on Rolled and Rigid Printing

Color, beyond imagination

Application, infinite possibilities

UV printing can be perfectly applied to flexible materials such as banner, flexible film, 3P cloth and rigid materials such as glass, ceramic tile, acrylic board, etc.

Explore & foresee the future

Integrating the current advanced printing concept, cutting-edge technologies contributed: high-precision metal grating with linear motor to ensure high-speed movement of printhead; constant pressure adsorption control system ensures stable material adsorption and creates excellent quality on printed images.

Extraordinary value

Stability means extraordinary value. With strict production requirements and process standards, it presents industrial quality and brings ultra long-lasting output.

Learn more about M3300

Switchable feeding system: air shaft safety clamp or double tube support for feeding. Easily switch, convenient feeding and printing without deviation.

LED lamp curing solution: using LED cold light source can effectively reduce energy consumption, be more green and environmental protection, and help sustainable development.

Motion failure solution: using safe and reliable towline solution to effectively prevent vibration and say goodbye to motion failure.

Ink supply system: stable sub ink tank temperature control system to ensure consistent ink properties in different environments. The whole machine adopts high-precision filter to ensure the quality of ink supply. A complete ink system is a powerful driving force to achieve stable and lasting output.

Stable adsorption: the platform adopts constant pressure control technology to ensure stable adsorption of materials and printing accuracy. The rigid printing adopts double pressing rollers and positioning device to make the positioning accurate.

High speed printing: X-direction adopts high-precision metal grating and linear motor to ensure high-speed and stable movement of printhead; high quality rubber belt in Y-direction to ensure accurate stepping without deviation, and mesh-like fringes abandoned.

Color management software: RIP software Caldera or PrintFactory adopted to support many mainstream applications, with simple and convenient operation interface.

M3300 Industrial Printer

Technical Specifications

Printing width 3200mm

Printhead Konica Minolta (6PL or 13PL) Kyocera KJ4A

Printing speed 单排 One Row 双排 Two Rows

Substrates Rigid media: glass, wood plate, ceramic tile, metal plate, acrylic board, PVC expansion sheet, crystal, marble, corrugated board.

Flexible media: flexible film, 3P cloth, fabric, wallpaper, leather, banner, reflective film, canvas and other flexible materials.

Printing thickness

Color C, M, Y, K, Lc, Lm, W

Environmental requirements 18-28℃

Connectivity

Machine power

Input voltage

Machine size

Machine weight

M3300 Industrial Printer Technical Specifications

| Printing width | 3200mm | |

| Printhead | Konica Minolta (6PLorl3PL) | Kyocera KJ4A |

| 6C+W 4C*3 |

4C (One Row) 4C(Two Rows) |

|

| 2 PASS 540* 720 dpi 60m2/h 180m2/h | 4 PASS 600* 1200 dpi 80m2/h 150m2/h | |

| 3 PASS 540* 1080 dpi 43m2/h 130m2/h | 6 PASS 600* 1800 dpi 65m2/h 100m2/h | |

| 4 PASS 540* 1440 dpi 31m2/h 90m2/h | 8 PASS 1200* 1200 dpi 45m2/h 80m2/h | |

| Rigid media: glass, wood plate, ceramic tile, metal plate, acrylic board, PVC expansion sheet, crystal, | ||

| marble, corrugated board. | ||

| Substrates | Flexible media: flexible film, 3P cloth, fabric, wallpaper, leather, banner, reflective film, canvas and | |

| other flexible materials. | ||

| Printing thickness | <50mm | |

| Color | C,M,Y,K,Lc, Lm,W | |

| Optimum temperature | 18-28°C | |

| Optimum humidity | 30%-70% RH | |

| Data transmission | PCIE | |

| Machine power | 11.5KW/19A | |

| Input voltage | 380V/50/60HZ | |

| Machine size | 6300mm x 1750mm x 1720mm | |

| Machine weight | 1950kg | |

Product detail pictures:

Related Product Guide:

We often stay with the principle "Quality Very first, Prestige Supreme". We have been fully committed to supplying our consumers with competitively priced high-quality goods, prompt delivery and skilled provider for OEM Manufacturer Inkjet Sublimation Paper - M3300 Industrial Printer – JHF , The product will supply to all over the world, such as: Provence, Milan, Bogota, Our staffs are adhering to the "Integrity-based and Interactive Development" spirit, and the tenet of "First-class Quality with Excellent Service". According to the needs of every customer, we give customized & personalised services to help customers achieve their goals successfully. Welcome clients from home and abroad to call and inquire!

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.